What is Polishing?

Polishing is a processing technique that uses fine, hard particles called abrasive grains to gradually remove the surface of a material and create a smooth finish.

It allows for precise processing down to the micrometer level, resulting in a beautiful glossy finish that improves appearance and helps prevent rust and dirt.

When even higher smoothness is required, advanced polishing methods such as mirror polishing, precision polishing, and ultra-precision polishing are used.

Ultra Precision Surface Polishing

Purpose

- LCD photomask substrates

- Touch panel photomasks

- Substrate

Processing Range Available

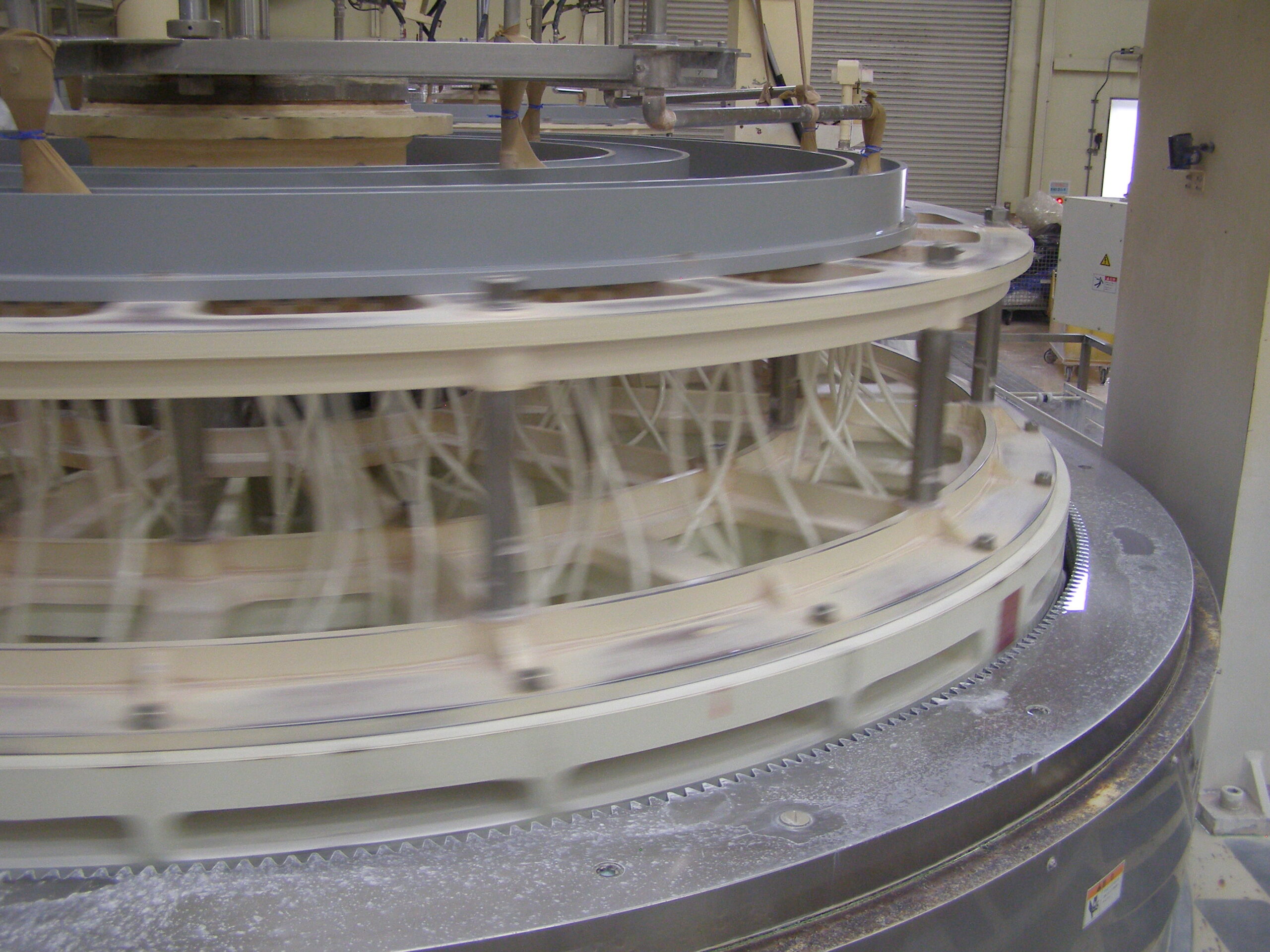

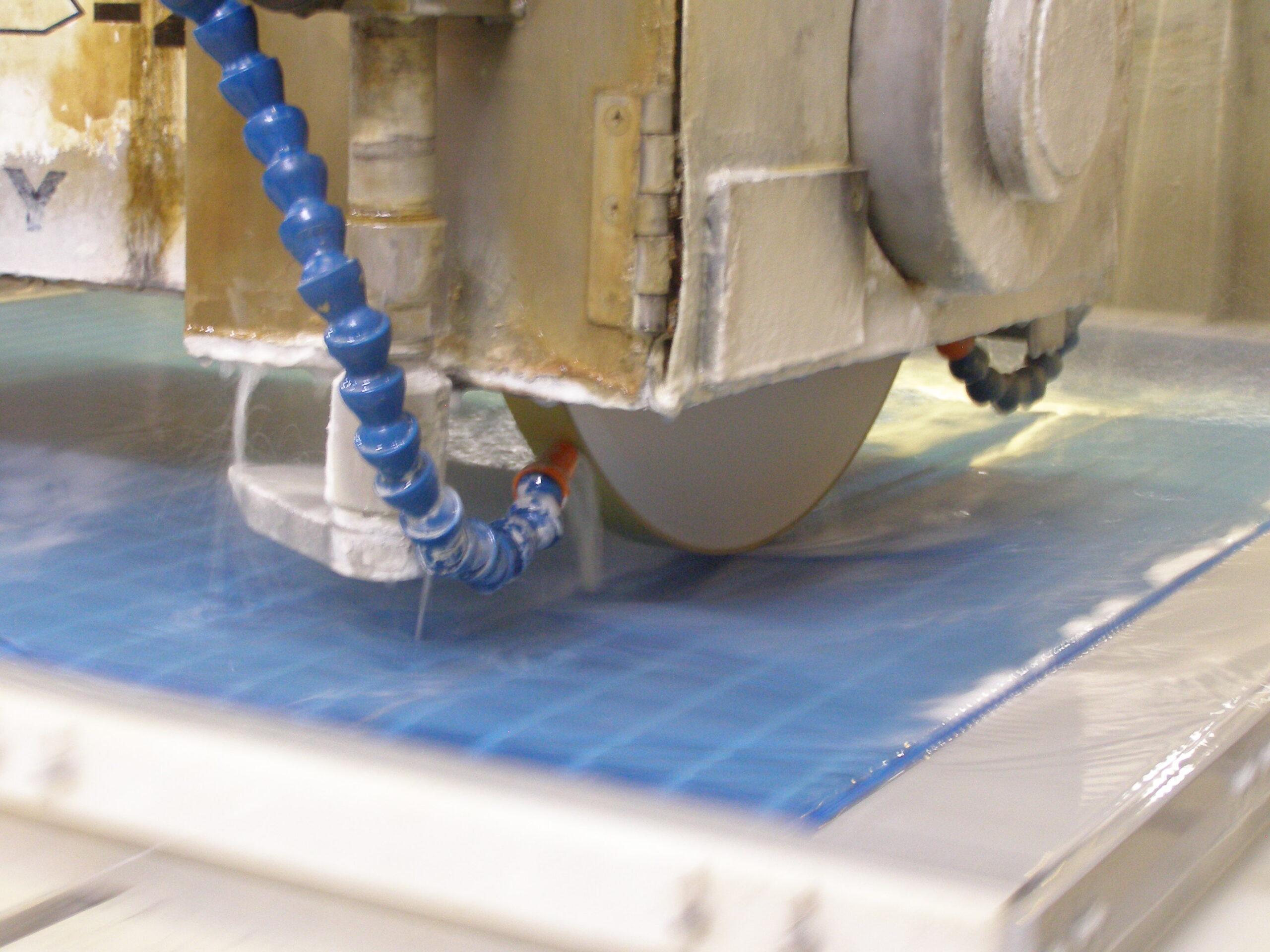

| Processing details | Lapping, polishing, final polishing, double-sided and single-sided polishing Glass material procurement – polishing – cleaning – inspection – packaging (cases) |

|---|---|

| Material | Quartz glass/Soda-lime glass etc… |

| Plate thickness | 2.3t–20t ± 0.01 |

| Size | [Quartz substrate] Supports up to 1700mm x 1800mm [Soda lime substrate] Supports up to 1900mm x 2100mm |

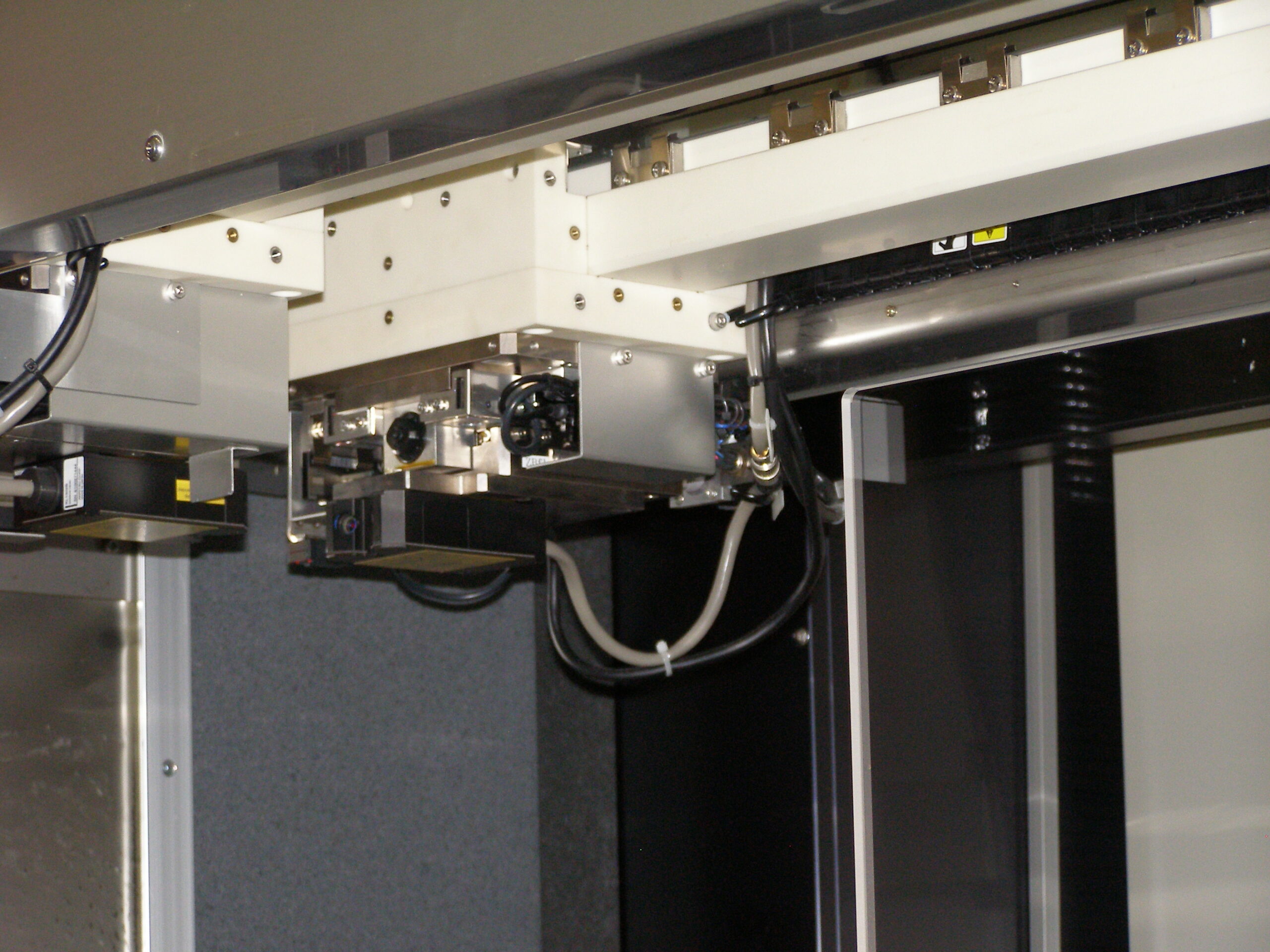

| plane measuring machine | Supports 1920mm x 2000mm |

| Flatness | 10μm or less/520mm×800mm |

| Inspection | Surface defects 2µm or less |

Q&A

Product/Processing Examples

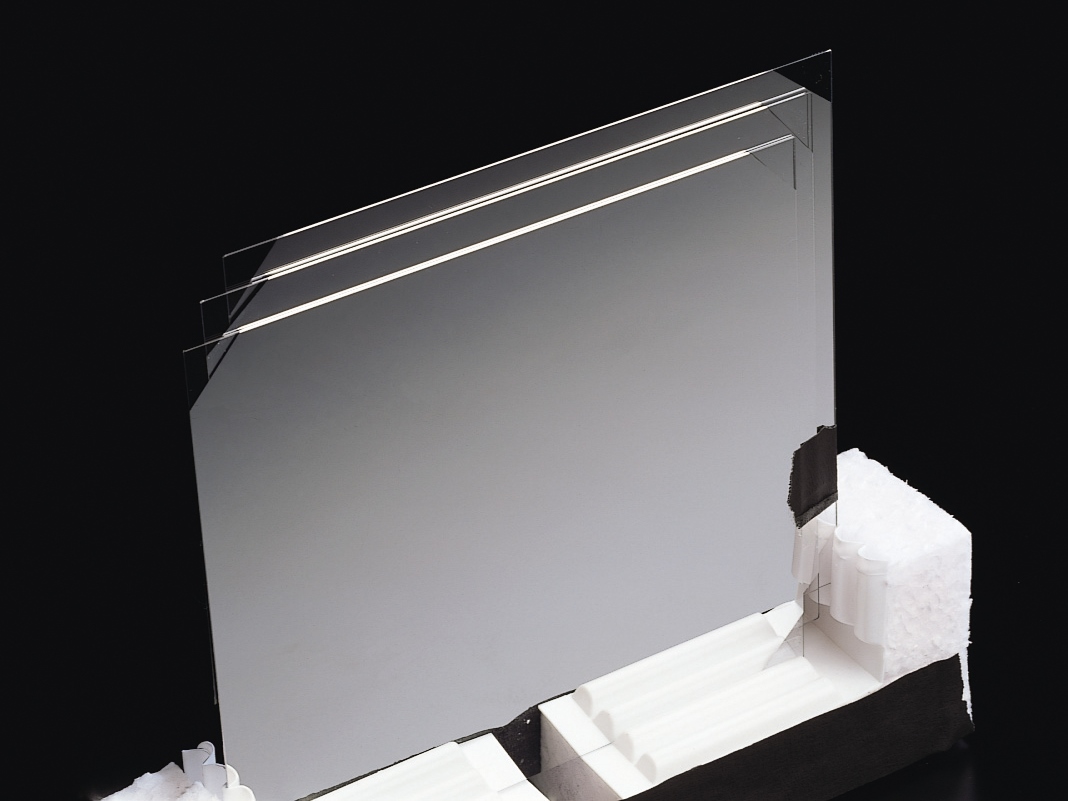

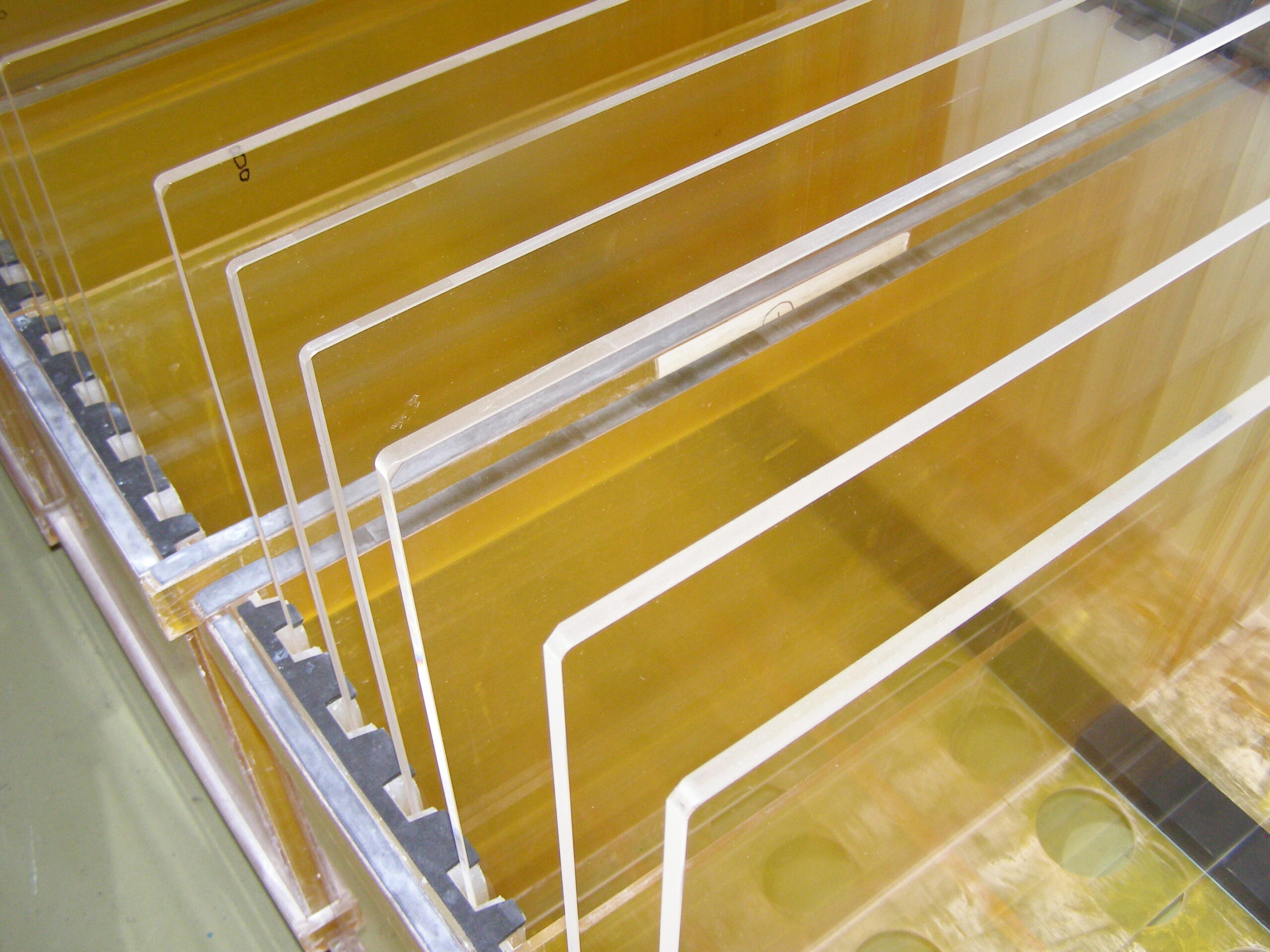

LCD Photomasks

In the FPD industry, where precision is increasing year by year, our company’s unique polishing technology meets the demand for high precision fine patterns and the trend toward larger substrates.

Our products are made from high-quality large-sized materials and processed using our extra-large double-sided polishing machines, meeting the strict requirements of our customers and allowing them to use them with peace of mind.